Stop recovery

This guide will cover various Stop recovery scenarios, introduced by either the robot, the user or the system. In all scenarios, the timing diagrams will show recovery through Dashboard Server commands send to the robot. It can also be done with manual interaction with the robot.

In order to recover with Dashboard Server commands, it is necessary to cover several prerequisites before being able to send robot commands:

Prerequisites

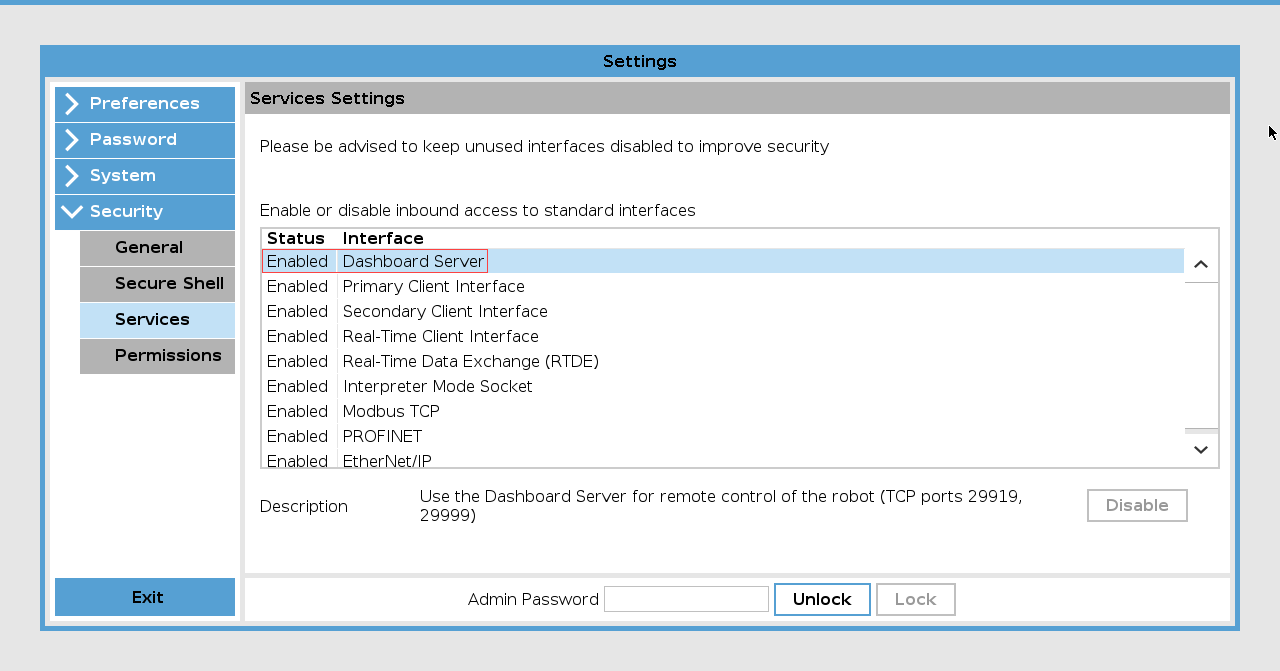

Robot has Dashboard Server access enabled:

Settings → Security → Services → Dashboard Server → Enable.

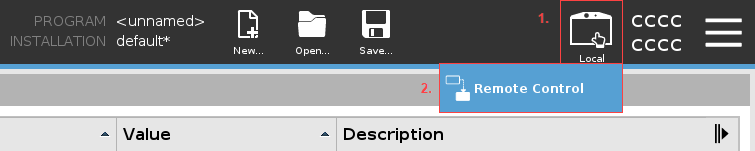

Robot in remote control mode:

Settings → System → Remote Control → Enable.

Enter remote control:

Program for testing sockets:

SocketTest (freeware), HyperTerminal, or similar.

Note

The communication is done through port 29999.

Static IP-address and subnet mask on PC, so it matches the robot:

Robot IP-address: 192.168.3.X → PC IP-address: 192.168.3.Y.

Robot subnet: 255.255.255.0 → PC subnet: 255.255.255.0.

For detailed information about the dashboard server, please refer to Dashboard Server e-Series, port 29999.

The timing diagrams are based on data from the RTDE interface to highlight the states of the robot. This interface can be accessed from both PROFINET and Ethernet/IP. For more information, please refer to our RTDE guide, PROFINET guide, Ethernet/IP guide and Fieldbus Register table.

Important

The RTDE.robot_mode state “Running” (7) is NOT the same as RTDE.robot_status_bits.is_program_running.

RTDE.robot_mode state “Running” (7) is when the robot is powered on and have released the brakes.

Byte 5 (Bit 32-39) in Fieldbus Register table

RTDE.robot_status_bits.is_program_running is when the robot is executing the program.

Bit 129 “PR” in Fieldbus Register table

Protective stop recovery

Note

A Protective Stop is a stop initiated by the robot controller due to the robot state’s proximity to a limit. The error codes following this messages, in most situations, can be the C153 or C157. A warning message is shown on the teach pendant display (or external display), as a notification of the condition. If your robot keeps showing Protective Stop warning messages during operation, pay immediate attention and perform an investigation to determine the their root cause. Investigate ALL Protective Stop warning messages. These messages are indicate that the robot’s application and/or the program needs to be reviewed. Program modification or servicing can be required before resuming operation.

For more information about protective stop, please refer to the Universal Robots protective stop service note

Step |

Description |

|---|---|

0 |

Robot is running in normal mode, executing program. |

1 |

Robot encounters protective stop and stops playing program, while retaining power. |

2 |

Dashboard server command “close safety popup” is sent to close the safety popup. |

3 |

Dashboard server command “unlock protective stop” is sent to unlock the protective stop. |

4 |

Safety mode returned to normal. |

5 |

Dashboard server command “play” is sent to play the program. |

6 |

Program is started from where it stopped. |

Robot Emergency Stop recovery

Note

Robot Emergency Stop performs a Stop Category 1 via Control Box input, informing other machines using the System Emergency Stop output, if that output is defined.

For more information about safety functions, please refer to the Safety Functions Table

Step |

Description |

|---|---|

0 |

Robot is running in normal mode, executing program. |

1 |

Robot encounters Robot E-Stop and stops the robot in an orderly, controlled manner. |

2 |

Robot is stopped and enters idle mode. |

3 |

User manually releases E-stop button → Safety mode goes to normal. |

4 |

Dashboard server command “close safety popup” is sent to close the safety popup. |

5 |

Dashboard server command “brake release” is sent to release brakes. |

6 |

Robot releases brakes. |

7 |

Robot starts running. |

8 |

Dashboard server command “play” is sent to play the program. |

9 |

Program is restarted from the beginning. |

System Emergency Stop recovery

Note

System Emergency stop performs a Stop Category 1.

For more information about safety functions, please refer to the Safety Functions Table

Step |

Description |

|---|---|

0 |

Robot is running in normal mode, executing program. |

1 |

Robot encounters System E-Stop and stops the robot in an orderly, controlled manner. |

2 |

Robot is stopped and enters idle mode. |

3 |

User manually releases E-stop button → Safety mode goes to normal. |

4 |

Dashboard server command “close safety popup” is sent to close the safety popup. |

5 |

Dashboard server command “brake release” is sent to release brakes. |

6 |

Robot releases brakes. |

7 |

Robot starts running. |

8 |

Dashboard server command “play” is sent to play the program. |

9 |

Program is restarted from the beginning. |

Safety fault/violation recovery

Step |

Description |

|---|---|

0 |

Robot is running in normal mode, executing program. |

1 |

Robot encounters fault/violation and stops executing the program. |

2 |

Robot goes to fault state and powers off robot. |

3 |

Dashboard server command “close safety popup” is sent to close the safety popup. |

4 |

Dashboard server command “restart safety” is sent to restart safety. |

5 |

Safety is restarting. |

6 |

Safety goes to normal mode. |

7 |

Dashboard server command “power on” is sent to power on robot. |

8 |

Robot is powerering on. |

9 |

Robot is booting. |

10 |

Robot enters idle mode. |

11 |

Dashboard server command “brake release” is sent to release brakes. |

12 |

Robot releases brakes. |

13 |

Robot starts running. |

14 |

Dashboard server command “play” is sent to play the program. |

15 |

Program is restarted from the beginning. |

PROFIsafe stop recovery

Note

If you are using PROFIsafe on you robot, the recovering process is the same for all the above mentioned scenarios, with exception of the safety fault/violation stop. This is because, when the robot encounters a safety fault/violation, it stops and powers off immediately. Then, when the robot is powered on again, the robot automatically enters a “PROFISAFE EMERGENCY STOP” state waiting for the user to acknowledge the error, before being able to power on.

PROFIsafe safety fault/violation recovery

Step |

Description |

|---|---|

0 |

Robot is running in normal mode, executing program. |

1 |

Robot encounters fault/violation and stops executing the program. |

2 |

Robot goes to fault state and powers off robot. |

3 |

Dashboard server command “close safety popup” is sent to close the safety popup. |

4 |

Dashboard server command “restart safety” is sent to restart safety. |

5 |

Safety is restarting. |

6 |

Robot enters PROFIsafe Emergency stop state. |

7 |

Dashboard server command “close safety popup” is sent to close the safety popup. |

8 |

“Acknowledge safety” signal is sent via PLC, button, etc. |

9 |

Safety goes to normal mode. |

10 |

Dashboard server command “power on” is sent to power on robot. |

11 |

Robot is powerering on. |

12 |

Robot is booting. |

13 |

Robot enters idle mode. |

14 |

Dashboard server command “brake release” is sent to release brakes. |

15 |

Robot releases brakes. |

16 |

Robot starts running. |

17 |

Dashboard server command “play” is sent to play the program. |

18 |

Program is restarted from the beginning. |